Products

Solution for you

Our solutions helps manufacturers to maximize their productivity by easy and efficient industrial robot programming. Our leading off-line programming software provides quick and easy programming tools for multiple applications, saving time and money while maximizing return on investment.

How we work

01

Integrate

The plug-and-produce installation methodology allows for same day installation and calibration. Months long installation times are a thing of the past

02

Upload

Programming with AddPath OLP is as easy as selecting the layup surface of your mold, inputting the fiber orientations, and uploading the resulting code to the robot

03

Produce

begin producing parts upon installation

04

Collaborate

we are supporting your company and also we can start to cooperate

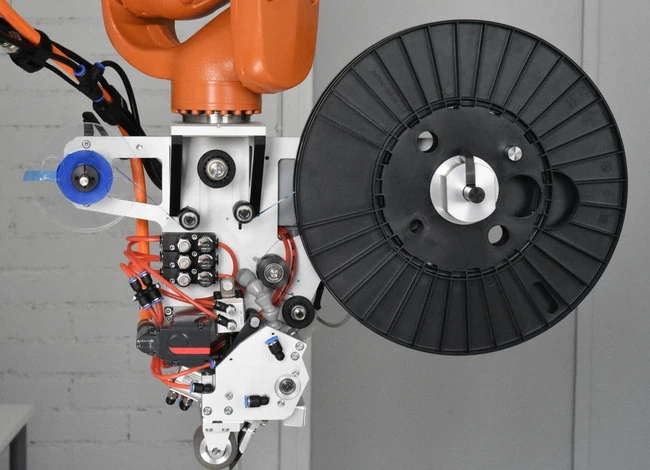

AFP-XS

Industries & application

Aerospace

Dish antennas, cabin accessories

Automotive

Door panels, spoilers

Bike seats, snowboards,

water paddles

Dish antennas, cabin accessories

Hydrofoils, bulkheads

- Sports & Leisure

Door panels,spoilers

Dish antennas, cabin accessories

Advantages

Single-fiber placement head with variable fiber width

Particularly suitable for local fiber reinforcement

Thermoset, thermoplastic, and dry fiber manufacturing capability

The AFP-XS by Addcomposites is capable of producing composite parts using various fiber and resin matrix materials. Enforcing its position as an ideal addition to any facility supporting research and development of processes, designs, and new materials.

The AFP-XS is the lightest, most compact end-effector available for automated composite layup. Simply attach the AFP-XS to an industrial robot via the Schunk quick change, install our Rhino 6® plug-in, and upload files from your current 3D modeling software.

Capable of handling traditional and natural material, transitioning to automated layup has never been easier.

Our plug & play approach enables short term use; the Schunk quick change allows for flexibility of robot use, including the length of time it is at your facility.

The AFP-XS is the lightest, most compact end-effector available for automated composite layup. Simply attach the AFP-XS to an industrial robot via the Schunk quick change, install our Rhino 6® plug-in, and upload files from your current 3D modeling software.

Capable of handling traditional and natural material, transitioning to automated layup has never been easier.

Our plug & play approach enables short term use; the Schunk quick change allows for flexibility of robot use, including the length of time it is at your facility.

Request specification

AddPath OLP Software

The software was built with the goal of accessibility and customization in mind. The open platform allows for different material uses, layup techniques, fiber paths, and mold shapes to be used.

The Rhino 6 plug-in requires minimal installation time, and since most universities/R&D centers/technical clusters have existing Rhino 6 subscriptions, there is no additional learning curve or infrastructure investments. AddPath requires Windows, see full Rhino requirements here.

Simply import your model, in .stp format, of the mold you will be using for layup, select the layup surface, then input the number and orientation of the desired layers. Our software will generate a preview of how the layup of each layer would look. With the option to suppress any unnecessary passes, selective reinforcement is achievable. After approval, the software will generate a simulation with collision detection. After everything is accepted, upload the file and resume production. Our toolhead communicates with the existing robot infrastructure to ensure seamless layup and communication.

The Rhino 6 plug-in requires minimal installation time, and since most universities/R&D centers/technical clusters have existing Rhino 6 subscriptions, there is no additional learning curve or infrastructure investments. AddPath requires Windows, see full Rhino requirements here.

Simply import your model, in .stp format, of the mold you will be using for layup, select the layup surface, then input the number and orientation of the desired layers. Our software will generate a preview of how the layup of each layer would look. With the option to suppress any unnecessary passes, selective reinforcement is achievable. After approval, the software will generate a simulation with collision detection. After everything is accepted, upload the file and resume production. Our toolhead communicates with the existing robot infrastructure to ensure seamless layup and communication.

Request specification

Evaluation & Pilots

When determining if an automated fiber placement system is the best investment for your facility, there are many options to consider. Our customer focused team is available to help you decide which option is right for you, no matter the outcome.

The transition to any new system doesn't come without obstacles. We are available to answer any questions that arise; before, during, and after implementation. We're here to increase your research capacity and opportunity for industrial collaboration. Not sure if you want to invest yet? Reach out to us for a pilot project of your desired application today! .

The transition to any new system doesn't come without obstacles. We are available to answer any questions that arise; before, during, and after implementation. We're here to increase your research capacity and opportunity for industrial collaboration. Not sure if you want to invest yet? Reach out to us for a pilot project of your desired application today! .

Request specification

Materials

With so many innovations coming from research projects, we'd be remiss not to mention the variety of materials that the AFP-XS can handle. With composite production, the main material that comes to mind is carbon fiber, and for good reason. However, we know there is so much more to composites, and so we set out to enable the advancement of composite research, fostering the growth and adoption of composites in everyday items.

Contact us today with your innovative project in mind, and we can get you started with AFP. Capable of accurate and repeatable placement using carbon, glass, and natural fibers, the AFP-XS has your project covered.

Contact us today with your innovative project in mind, and we can get you started with AFP. Capable of accurate and repeatable placement using carbon, glass, and natural fibers, the AFP-XS has your project covered.

Request Material Evaluation